Today the Aluminium Weaver Mk3 project begins.

Planned timelines: 3-6 months.

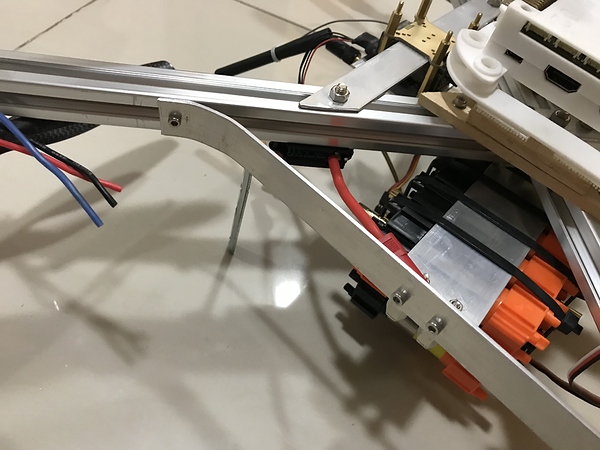

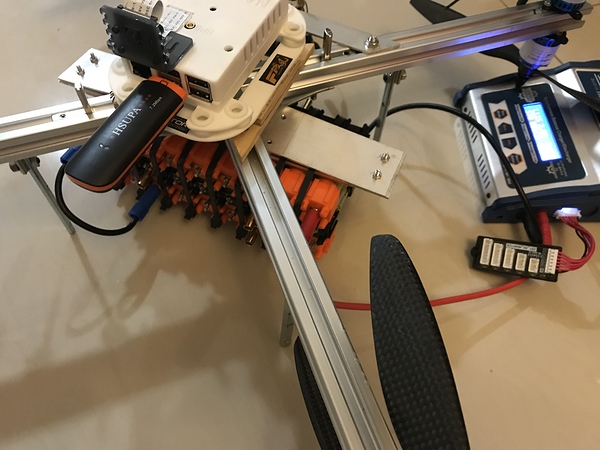

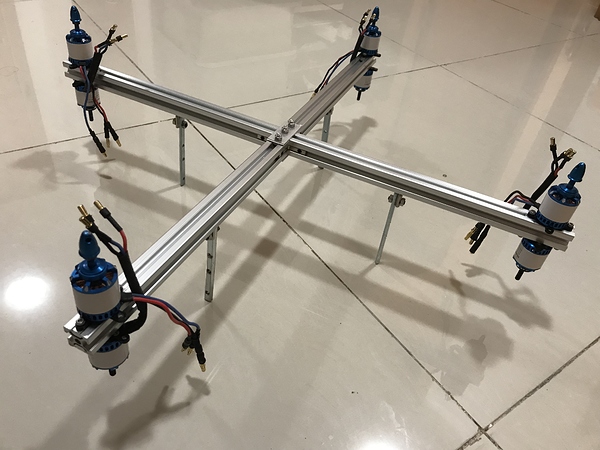

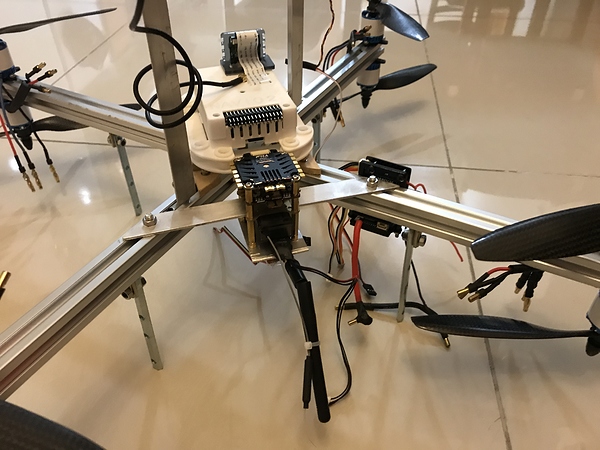

Frame type: Coaxial Octo-X 600mm.

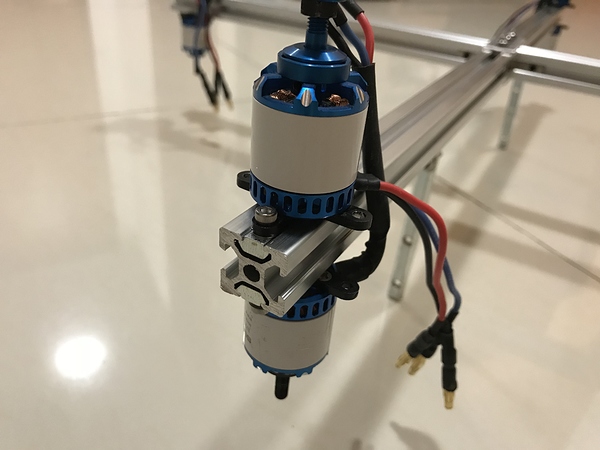

Motors: 8x2216 Sunnysky v3 880kv (just I have them; after tests may have to change to lower kv).

Props: 1045 carbon no-name (again, just I already have them).

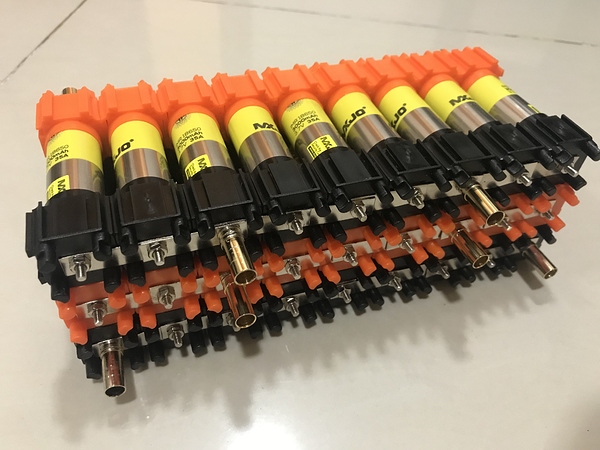

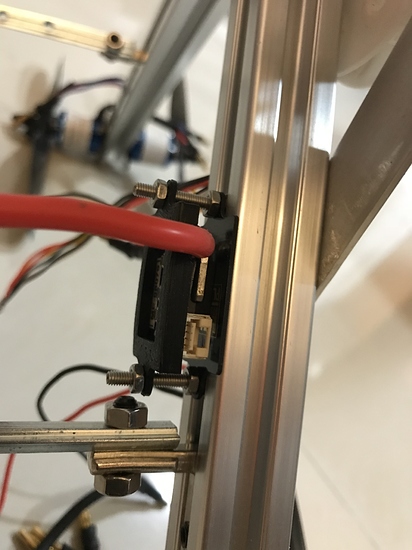

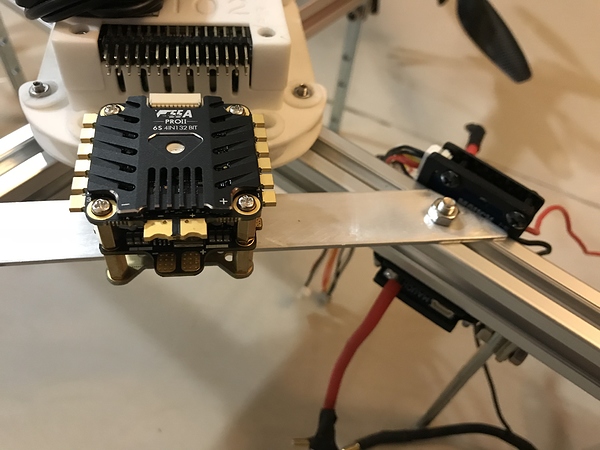

ESCs: 2x4-in-1 at least 40A, my DALRC showed itself just brilliant.

Power system: 5-6S 15000-20000mAh Li-Ion. I am going to pay special attention to this part and manufacture it fully myself. This will require to learn about the Li-Ion battery protection/charging circuits and may take more time. I am planning to manufacture a custom enclosure for pack using wood and aluminium.

Now what’s special about this project?

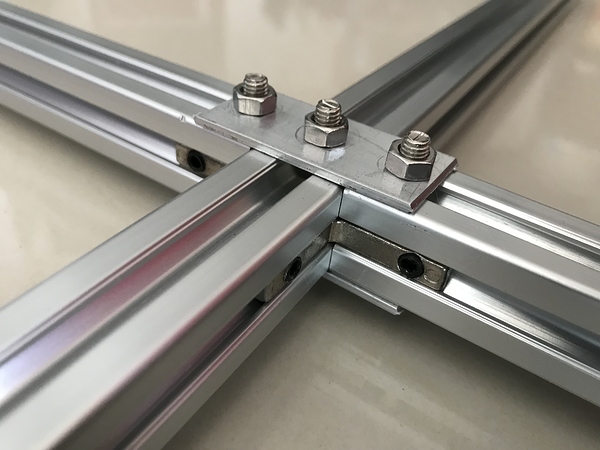

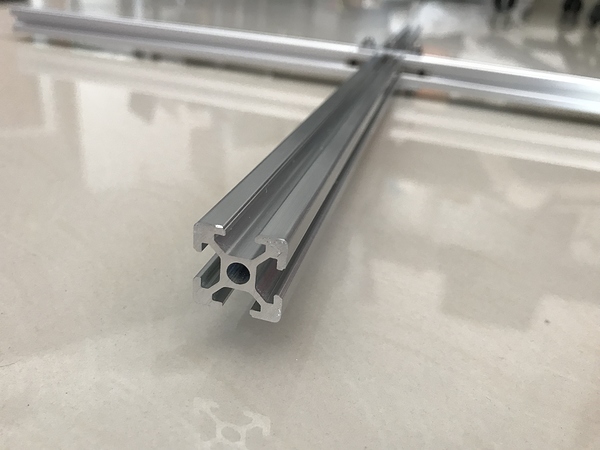

Ladies and Gentlemen, first time in History - a drone is made - using 2020 Aluminium Profile for 3D-printers!

Same as below:

2x600mm bars weight 600g total. That’s more than the carbon one by ~200g - but much more customizable and presumably stronger.

Apart from other smaller benefits, it gives supreme modularity - using a number of mounting brackets, bolts and nuts. Configuration can be changed in seconds - without any drilling.

Mount LED lighting, landing gear, gimbal, batteries, scale the configuration - with minimal efforts and thoughts!

Please share your thoughts, suggestions and inputs.

I am inviting this initiative to be part of the community.

Updates will be posted here.

Current status - waiting for arrival of mounting gear from Aliexpress; arriving in 10-15 days.

Thank you.

On T-Motor ESC I didn’t research that. Got to research and find out.

On T-Motor ESC I didn’t research that. Got to research and find out.