I am very interested in this conversation although I think it has drifted from navio. @Kylerlaird - are you using the navio at all or are you feeding the dual RTKdirectly into micro ? I have been working on a vineyard rover and my expericiece with compass/IMU is poor. I think the large amount of metal, EMI, and vibration do the compass/IMU in. I have a North RTK and I am going to add a second receiver to give me heading as inspired by your work. Then use a LIDAR I have lying around to get some obstacle avoidance. My vehicle is tracked - weighs about 900 Kg and runs at 1 m/s. Gas powered 26 hp.The one advantage of APM is the gcs available. It is nice to see and plan waypoints on a map. But perhaps,I can just use MAVLINK to display positions and leave control to ROS. Like Mr 337, I think the RP3 is too puny to handle ROS and perhaps the nvidia TX1 is the controller of choice.

vinorobo, this has indeed drifted from the Navio. I would love to be able to use a Navio but it’s just not adequate for me. There is work toward moving APM toward Robot Operating System, but I don’t expect that soon.

Before you rule out using an IMU, try an IMU Brick 2.0. I’m thinking I might incorporate one into my current project (a JD 6330).

I definitely disagree that the RPi3 is too puny for ROS. I worked my grain cart almost every day for months and it worked surprisingly well. I’ve been hacking on a SeedSense 20/20 recently and I’m thinking about using it for some of the control. There are also opportunities for offloading some operations to Arduinos, etc.

This morning I ordered the new Tersus BX316. If it works as expected, it’ll be a great addition.

I’ve been thinking about adding LIDAR so I can navigate next to semi-trucks. I’m a bit more inclined to use microwave, though.

Eventually I need to tackle map display, mission planning, etc. I’m kind of dreading that so feel free to do the development work and share it with me…

–kyler

I am very intersted in installing similar units but It seems to me you are on a newer tractor with electronic steering. My tractors are standard power steering. wondering if you have any reccommendations on aftermarket additions that work with the reach platform.

thanks

adam

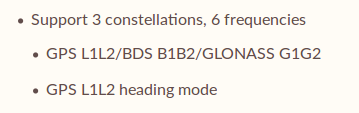

Let me know how the BX316 turns out. I got a call from Tersus and it was sooo painful to coordinate with them. Example, the BX316 shows it has heading but only for GPS ??

When questioning this I got a long silence, than I asked again followed by we will change the “blog”? I’m like this needs to be validated as your other docs agree with this but I don’t know why heading is only using GPS L1/L2.

My understanding is you’ll need to find an autosteer system for your tractor. This isn’t my field but I have talked with a few other farmers and they said their protocols are open and easy to interface. kylerlaird would def have a more solid answer, but hope this helps.

Adam,

My first two projects had standard hydraulic steering systems. On the first (JD 420), I ripped out the existing hydraulic system and replaced it with my own. On the second (MF 2745), I added my valves in parallel with the steering valve. In both cases, I used “bang-bang” valves which had coarse control. Those valves are around $100.

For my third project (MT 765) I was delighted to use the electronic steering. I was unable to figure out the CANbus control system and suspected that it would be too limited so I just mimicked the steering wheel sensor. It’s super easy.

For my current project (JD 6630), I decided to use a Trimble steering valve system. It was $3K or so but I feel better having a well-engineered system on this tractor. It’s proportional so I will have much finer control. I only had the valves installed so I still need to connect controllers to the solenoids and add a steer angle sensor.

I am very interested in a tractor with an open protocol for steering.

(I would love to be able to easily control the steering on my JD 8285R through CANbus but Deere is so damn proprietary that I’ll probably just trade it for another Challenger.)

–kyler

Very helpful, appreciate this. I was considering an official solution for around 3k if i can use the REACH RTK with it. As the RTK ssytems i was lookign at was pushing itself into another years budget! So you currently are using REACH with the Trimble steering? Am i crazy to look at adding proportional valves on my own opposed to their solutions? I guess i’m unsure if the error reduction is a function of the RTK, the trimble proporietary system, or both. WHats your felling?

So your trimble system is hydraulic not a steering wheel based solution right? Do you have that kit #, i’ve only seen alot of ones that clamp on the steering wheel.

thanks

adam

[Oops! I thought I posted this a long time ago but here it is, staring at me in the preview…]

Adam,

I believe I have a Trimble 54035(-160 or -163?) kit installed on my JD 6330. I don’t have the final order in front of me now but that should get you started. Yes, it’s directly controlling the hydraulic steering cylinder. Those steering wheel based systems feel messy to me. I am resurrecting my first project (a JD 420) and plan to put proportional valves and dual RTK on it. I’ll be able to say more about the feasibility once that’s done.

I do not use REACH. It would be great if Navio became a collection of Robot Operating System (ROS) nodes so that I could easily do what I want with it, but it was more than I could solve so I’ve been using the NVS-08C-RTK-A dual L1 receiver and a Raspberry Pi3. I have a Tersus Precis-BX316 dual GNSS receiver on order for my current project.

For planting corn, I definitely want RTK. I don’t see any good way around that. (And RTK is fairly cheap now so I’m not motivated to look.) Proportional control sure does make a difference. Whether or not I’m able to do as well as Trimble at line following is still unknown.

–kyler

Kyler

I’ve been looking at buying a Tersus Precis BX316 for quite a while but I’ve given up and bought an NVS NV08C-RTK-A receiver instead. I bought TW2706 antennas because NVS said they will have Galileo fw in a few months.

I just can’t find any information from an independent source on the BX316 or the BX305. I would be very interested in find out how well the Precis BX316 work. Tersus told me in an email that they would ship the BX316 by end of March. I hope they do.

Larry

Larry,

Yes, I was told March also. I plan to run automated tractors on both corn and beans this year so I will probably just use my NVS receivers rather than wait for Tersus. It might be awhile before I have any experience with Tersus to share.

–kyler

Kyler

I asked Tersus again when they plan to start shipping the BX316 and now they say April.

There are 18 Galileo satellites in place so having antennas like the TW2706 that support the Galileo constellation should give some help in keeping a Fix. I make my own containers for GNSS antennas using a 3D printer. I need to keep the weight of my octocopter as low as possible.

Larry

Larry,

Thanks for the update.

After they told me “March” I expected it to slip well beyond that. I’ve been tentatively planning on using my NVS receivers for planting this year. Looks like that’s definitely what I need to do.

–kyler

Kyler

I noticed you are interested in radar and so I’ll show you the ones I’m looking to use on my farming UAV.

The $550 Ulanding radar from - http://aerotenna.com/sensors/

and a $10000 very interesting radar from - http://echodyne.com/products/

Larry

It’s time for an update. I think my latest project, Tractobot03, a 105 HP JD 6330, is closer to what some others might want to build than my 300 HP Tractobot02. I’m building it to pull an 8-row integral corn planter. That means it needs to drop the planter, drive 4 MPH in a straight line, raise the planter, turn, and do it again for about 70 hours.

transmission

There’s a left-hand mechanical reverser on this tractor. An electric reverser is an option for the Premium (cab) version but retrofitting it would be complicated and Deere refused to help. So I used a linear actuator. It’s not ideal, but it works.

I drive the actuator motor with an Arduino Nano and H-bridge module (L298N DC Stepper Motor Dual H Bridge L298N Drive Controller Board Module | eBay). The feedback goes directly to an analog input on the Nano where PID control is used so I can find neutral.

There’s also a four speed power shift which I might control in the future. I’m hoping that I won’t need it.

steering

The pressure-flow compensated hydraulic system was more complicated than I wanted to tackle so I paid ~$3K to have a commercial (AgLeader?) hydraulic steering control added. It basically comes down to two solenoids. (I think there’s also an output for steering wheel override but I haven’t played with it yet.)

I’m driving the solenoids with a MOSFET 4 module (http://www.ebay.com/itm/222008068156). Feedback comes from a Delphi ER10031 Suspension Sensor (http://www.ebay.com/itm/291800725443) which directly feeds an analog input on the Nano where PID control is used to direct the steering to a desired position.

ignition

I tap off of the ignition key switch for power and then send back power to the “ignition” (fuel) system through an SSR.

I could easily connect to the starter, too, and be able to remotely start the tractor (as I did with Tractobot00) but I’m resisting. Ideally, this tractor will start, run for several days, and stop. Remote start would not be very useful and would introduce the risk of grinding/burning the starter if it’s incorrectly engaged.

hitch

The hitch control is just two pushbuttons. (There’s also a height adjustment but I’ll set that locally.) Because I had a bunch of SSRs handy and I wasn’t quite sure about the signals on the switches, I used the SSRs.

throttle

The foot throttle is a potentiometer-like analog control. (I assume it’s a Hall Effect sensor but didn’t check.) I have not yet wired it to a PWM output of the Arduino. That’s one of my next steps.

enclosure

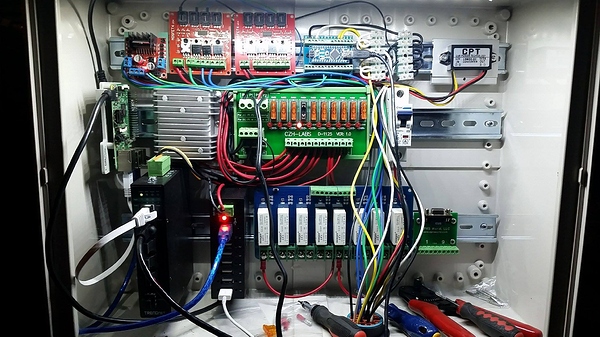

I’m using a plastic NEMA box (https://smile.amazon.com/gp/product/B005T5FMO0/ref=oh_aui_search_detailpage). I added DIN rails to hold everything.

software

I’m running ROS on a Raspberry Pi 3 with my own Python scripts. I’m trying to keep my code in Github (GitHub - kylerlaird/tractobots: field robots). It’s not completely up to date yet. I’m planning to integrate Github with my projects.

results

I put it all together and it seemed to work so why not try driving it out of the shed? (ROS joystick node running on my laptop.)

It was getting dark but I ran it a bit and it worked well.

The hitch also works.

future

I need to add a GPS receiver, long-range wireless network, and cameras. I’m working on an independent radio kill switch system. The planter will be controlled by a Precision Planting SeedSense 20/20 which is a very hackable Linux box. I will be able to use it via SSH/VNC.

It’s time for an update. I think my latest project, Tractobot03, a 105 HP JD 6330, is closer to what some others might want to build than my 300 HP Tractobot02. I’m building it to pull an 8-row integral corn planter. That means it needs to drop the planter, drive 4 MPH in a straight line, raise the planter, turn, and do it again for about 70 hours.

transmission

There’s a left-hand mechanical reverser on this tractor. An electric reverser is an option for the Premium (cab) version but retrofitting it would be complicated and Deere refused to help. So I used a linear actuator. It’s not ideal, but it works.

I drive the actuator motor with an Arduino Nano and H-bridge module (L298N DC Stepper Motor Dual H Bridge L298N Drive Controller Board Module | eBay). The feedback goes directly to an analog input on the Nano where PID control is used so I can find neutral.

There’s also a four speed power shift which I might control in the future. I’m hoping that I won’t need it.

steering

The pressure-flow compensated hydraulic system was more complicated than I wanted to tackle so I paid ~$3K to have a commercial (AgLeader?) hydraulic steering control added. It basically comes down to two solenoids. (I think there’s also an output for steering wheel override but I haven’t played with it yet.)

I’m driving the solenoids with a MOSFET 4 module (http://www.ebay.com/itm/222008068156). Feedback comes from a Delphi ER10031 Suspension Sensor (http://www.ebay.com/itm/291800725443) which directly feeds an analog input on the Nano where PID control is used to direct the steering to a desired position.

ignition

I tap off of the ignition key switch for power and then send back power to the “ignition” (fuel) system through an SSR.

I could easily connect to the starter, too, and be able to remotely start the tractor (as I did with Tractobot00) but I’m resisting. Ideally, this tractor will start, run for several days, and stop. Remote start would not be very useful and would introduce the risk of grinding/burning the starter if it’s incorrectly engaged.

hitch

The hitch control is just two pushbuttons. (There’s also a height adjustment but I’ll set that locally.) Because I had a bunch of SSRs handy and I wasn’t quite sure about the signals on the switches, I used the SSRs.

throttle

The foot throttle is a potentiometer-like analog control. (I assume it’s a Hall Effect sensor but didn’t check.) I have not yet wired it to a PWM output of the Arduino. That’s one of my next steps.

enclosure

I’m using a plastic NEMA box (https://smile.amazon.com/gp/product/B005T5FMO0/ref=oh_aui_search_detailpage). I added DIN rails to hold everything.

software

I’m running ROS on a Raspberry Pi 3 with my own Python scripts. I’m trying to keep my code in Github (GitHub - kylerlaird/tractobots: field robots). It’s not completely up to date yet. I’m planning to integrate Github with my projects.

results

I put it all together and it seemed to work so why not try driving it out of the shed? (ROS joystick node running on my laptop.)

It was getting dark but I ran it a bit and it worked well.

The hitch also works.

future

I need to add a GPS receiver, long-range wireless network, and cameras. I’m working on an independent radio kill switch system. The planter will be controlled by a Precision Planting SeedSense 20/20 which is a very hackable Linux box. I will be able to use it via SSH/VNC.

Kyler

Have you considered using a 4g Verizon wireless connection for control and video?

In Minnesota, Land O’Lakes has a contest that will have the contestants use a Verizon 4g connection for the UAVs.

Teams | Land O’Lakes Prize: Drone Challenge | HeroX.

There’s a number of open source projects for UAVs and a 4g on the internet. I have used the CORS network for RTK GPS with 3g Verizon and it worked quite well.

Larry

I use a Pantech UML295 Verizon 4G LTE Aircard (USB) in Tractobot02 for both CORS and remote control. I have a few of the Pantech adapters and will probably put one in Tractobot03. Unfortunately, the location for agBOT Challenge does not have Verizon service.

Neat stuff.

Are you using a Navio at all or just the R Pi and an arduino with ROS?

What are the latest thoughts of ROS vs a Navio2 ardupilot type of solution?

There’s an active discussion in the technology section of Thecombineforum.com that is exploring auto steer systems. You could contribute a lot to that. Look at low cost RTK and AgopenGPS threads.

John,

I am just using the RPi with an Arduino and ROS (with my Python scripts). Last weekend I completed “full control” of the tractor. I now have all of the controls I need for planting.

I appreciate being able to use off-the-shelf solutions when I can. I really wanted Navio to work for me but it felt too cumbersome to work around it. ROS is definitely what I need to use for future projects, so I’d rather invest my effort in it now. The only thing I’d want from Navio is better guidance. But I’m not so sure it would be a huge improvement over what I do with a dual-RTK receiver.

From what I’ve read, I think Navio is moving toward ROS. I hope that’s true. If Navio becomes a bunch of ROS components, I’ll certainly take advantage of it.

AgOpenGPS looks very interesting and I hope to use it in future projects. I’m really tempted to use it for my 31-row soybean planter this year. I’m planning to put a Precision Planting monitor on it but it would only be for monitoring, population, and section control. It looks like AgOpenGPS could probably handle it. I’m going to make sure I’ve got my corn planter working first.

I’ll check out thecombineforum.com. Thank you.

–kyler

That is a pretty nice looking setup there. I think I need to get a bigger box for my project so I can keep the wiring from turning into a rats nest.

The (BUD) enclosure has been wonderful. DIN rails are great. I need to get an earlier bot going next week (to do vertical tillage) and I’m kind of dreading dealing with the wiring in it. It’s a lot simpler but it’s not as well organized.

Yesterday I was interviewed by the local paper. I got my Tractobots together for the first time:

I hope to add a fifth soon.

Also, I’m building new kill switches. I’m using Adafruit 32u4 LoRa Feathers (Adafruit Feather 32u4 RFM95 LoRa Radio- 868 or 915 MHz [RadioFruit] : ID 3078 : $34.95 : Adafruit Industries, Unique & fun DIY electronics and kits). I am loving them. The range with a 3" piece of wire is amazing. (I still think of those worthless walkie-talkies I had when I was a kid!) Having an Arduino on each end makes for lots of possibilities. Highly recommended.